This article was published as a part of the Data Science Blogathon.

Introduction

Data Science has been a hot topic for many years now. We can all see daily examples in our personal and professional lives of how data science is applied to the Internet of Things (IoT). However, did you know that it has also become part of the Industrial Internet of Things (IIoT)?

The IIoT refers to the application of IoT technologies to manufacturing and industrial environments, and Data Science plays a special role in this sector.

In this article, we will explore the concepts of IoT and IIoT to understand better how Data Science and Machine Learning can be applied in these sectors.

Source: Shapelets.io

What is IoT?

The internet of things (IoT) is the network of physical objects that are embedded with electronics, software, sensors and network connectivity which enables them to collect, exchange and communicate data.

A growing portion of IoT devices is created for consumer goods, including connected vehicles, home automation, wearable technology, connected health devices, and appliances with monitoring activities. Businesses and society depend on the data obtained from these IoT sectors and their activities. For example, the medical and healthcare industry will use this technology to monitor and analyze patient health; also, transportation technology will need the integration of communication, control, and information processing across the systems, etc.

We arrive at the industrial sector if we continue applying IoT to different sectors. This is where the concept of the Industrial internet of things (IIOT) emerges.

Now, why is the IoT so important in an industrial environment? Let’s have a look, shall we?

Source: Shapelets.io

What is IIOT?

The Industrial Internet of Things (IIOT) refers to the connectivity between sensors, instruments, and other devices in manufacturing and energy management.

In other words, these devices are connected to industrial equipment and help with data analysis, operational technology, locations, and people. So it englobes the manufacturing, the agriculture, and the maritime industry.

The objective of this technology here is to monitor, analyze and automate the streamlining to optimize it and lower production costs. IIoT is enabled by technologies such as Cyber-physical systems, Cloud Computing, Edge Computing, Big Data, Artificial intelligence, and machine learning. This is where we arrive at the application of Data Science.

How is Data Science applied here?

The system configuration of the industrial Internet of things is segmented into three groups: first, the cloud, where all the data is stored, transformed and analyzed. The second is the network where the devices interact, and the third is the edge, which controls all the machines.

The implementation of data science to solve a problem is cyclical. It requires visualizing the data for any issues, taking action, understanding the business need, and implementing a machine learning model.

Since the industrial industry can be decomposed into five main technologies, let’s look at each and see how Data Science can be applied to solve each problem.

1. Cyber-physical

A cyber-physical or intelligent system is a computer system in which the mechanism is controlled or monitored by a computer-based algorithm. In these systems, software and hardware are deeply interwound, allowing them to interact with each other and share the data on the cloud.

Data science is an incredible asset for detecting anomalies, performance issues, or cost-saving detection in the algorithm and the machine. For example, when monitoring a cyber-physical process, the algorithm will register the data from the hardware and adjust its behavior depending on the required task. However, from time to time, the software or the hardware deviates from its original purpose and causes problems in the whole supply chain.

By running an anomaly detection analysis, the data scientist will be able to detect if there is any outlier, change in events, or even drift in the data set. In short-term anomalies, detection can save a couple of seconds to hours of work, which may result in a high opportunity loss.

2. Cloud Computing

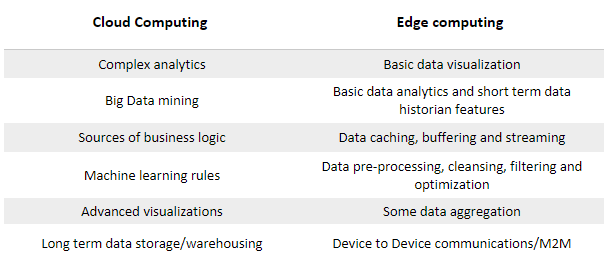

Cloud Computing is the on-demand availability of computer system resources for storage and computing power without the need to possess the hardware. Cloud computing in IIOT is useful for complex analytics, big data mining, advanced visualization, and long-term data storage. Moreover, one of its main advantages is its data centralization. For example, gathering all the data on one server in a windmill field would be easier than going to each turbine and downloading it.

In a typical data storage, the data is pushed to a server and then pulled back by a client; cloud computing is unsuitable for real-time data where time is critical in a supply chain. On the other hand, the Cloud Computing system is perfect for more complex analyses requiring a large amount of computing power. For example, predictive maintenance is a service that requires using cloud computing to extract when the company needs to repair a machine.

3. Edge Computing

Edge computing is a distributed computing paradigm that brings computer data storage closer to the location where it is needed. In contrast to the cloud, edge computing refers to decentralized data processing at the network’s edge.

The main advantages of the edge are real-time data analysis and control of the machinery. It allows basic data visualization/analytics, a constant flow of data, pre-processing/ filtering, and devices to devices communication.

Accessing an edge computing device allows one to diagnose the machinery and determine its functionality and efficiency quickly. For example, in a windmill field, the essential data needed to diagnose the turbine is more efficiently delivered without relying on patchy cellular communications with a cloud-based solution.

Differences between Cloud and Edge computing

4. Big Data

While cloud computing deals with computing power and storage, big data is the analysis of a vast amount of data that requires enough computing power to deal with it. The current usage of big data refers to predictive analysis, behavior analysis, or advanced analysis that takes advantage of extracting knowledge from big data.

Big data computing is essential in the industrial environment because of all the devices connected to the machinery (Visual sensors, Heat sensors, communication protocols, WIFI, Bluetooth, etc.). By analyzing the data issue by the captor, it became easier to predict the evolution of the machinery (machine failure, maintenance analysis) and its efficiency (productivity, expected productivity).

5. Artificial intelligence

In short, Artificial intelligence or AI is a field within computer science in which intelligent machines are programmed to react like humans. Machine learning or ML is a core part of AI that aims to predict the outcome without being explicitly programmed accurately. AI and Machine learning are applied in IIOT to predict the outcome of machinery thanks to big data.

Conclusion

Data is generated daily in different sectors, especially in the IoT and industrial environments. This is why businesses and professionals need better tools and technologies to find, collect and analyze every insight and anomaly of each process. Now, technologies such as Data Science and Machine Learning can help us get the best out of the data obtained from industrial devices.

In this article, we explore the concepts of IoT and IIoT, how they obtain data and how this can be used for better prediction and issues detection. In short, this article covers the following key subjects:

– Concept of IoT.

– Concept of IIoT and how it is useful.

– How Data Science is used in the 5 main technologies of IIoT.

– How these applications help businesses make the most of their data.

I find that knowing how Data Science and Data Analysis can be applied in different sectors is critical for improvement. To better understand our businesses and processes, we need to understand the data we get from them. This is how data science analysis can be the answer.

If you have any doubts or further questions, please use the comments section or, you can always visit my LinkedIn profile or contact me through the Shapelets website. I will be happy to assist you with your professional project.

The media shown in this article is not owned by Analytics Vidhya and is used at the Author’s discretion.